Guitar building overview

01Preparation

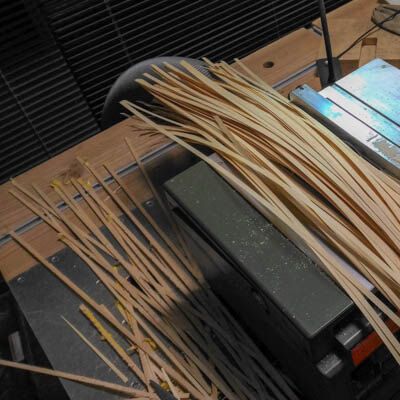

All wood parts from top plate to linings are resawn and cut out from lumber except for very thin (0.3mm to 0.5mm t) veneers used for purflings.

Well-seasoned lumbers are coming from specialty wood lumber mills either domestic or overseas.

Billets are resawn for top and back plates, and further seasoned in the workshop.

Sides are resawn from the same lumber as back plates.

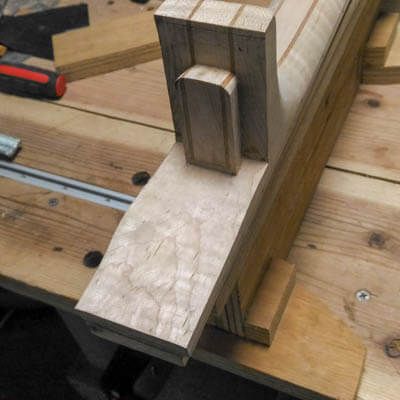

Neck blanks

02

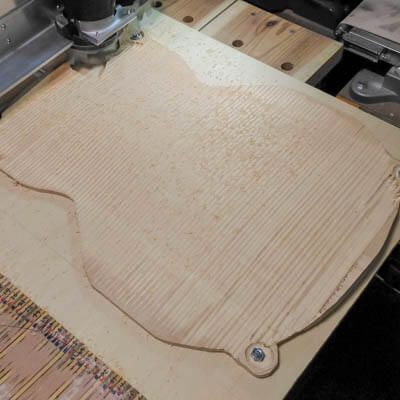

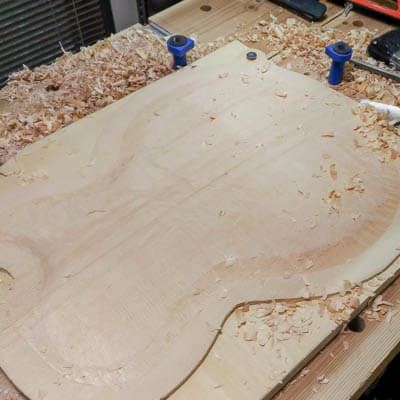

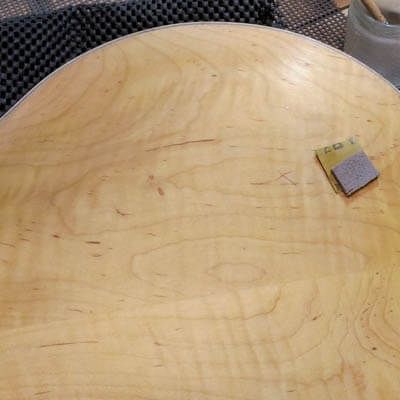

Body

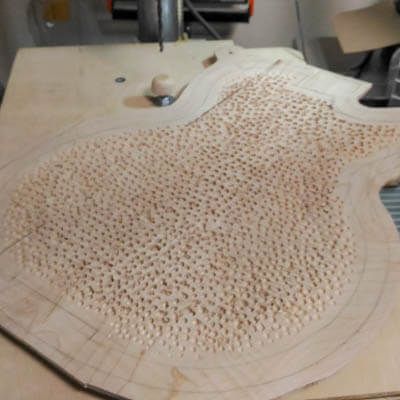

X bracing is standard. Parallel bracing is adopted for the case of body mount pickup model.

Gluing the back and top plates to the sides

Shellac is coated inside before closing the box. Hide glue is used for back and top plate gluing

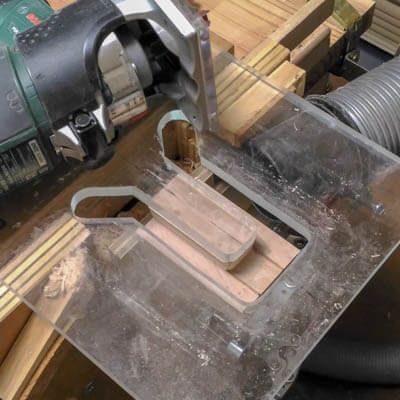

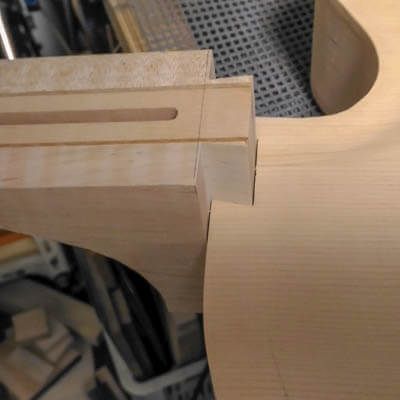

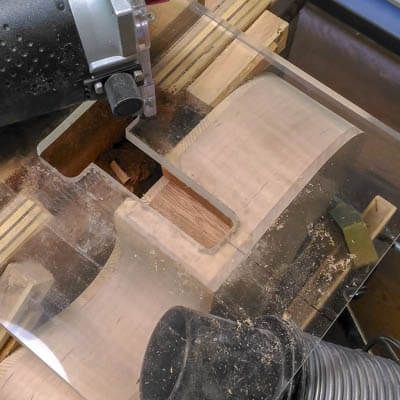

Cutting the body mortise

03Neck

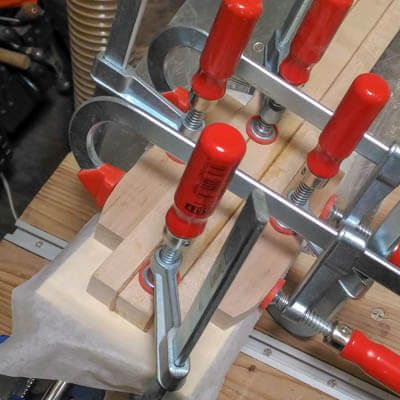

Gluing laminated neck blanks

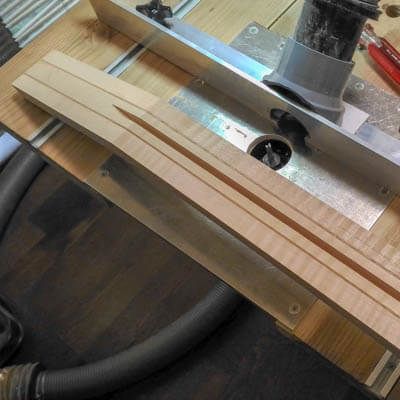

Cutting the truss rod groove

Planing the rear of the headstock

Gluing headstock veneers

Cutting the headstock shape

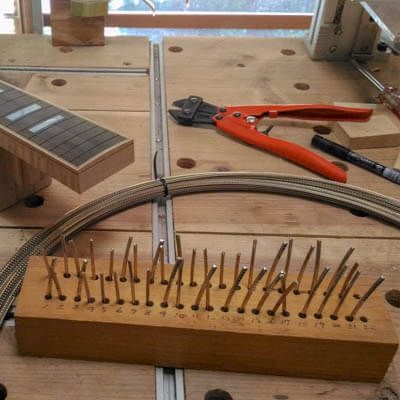

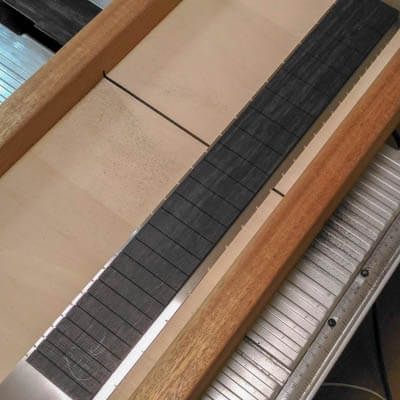

Slotting fingerboard

Teparing the fingerboard and gluing to the neck with hide glue

Binding the fingerboard

04Finishing

Scraping the recurve

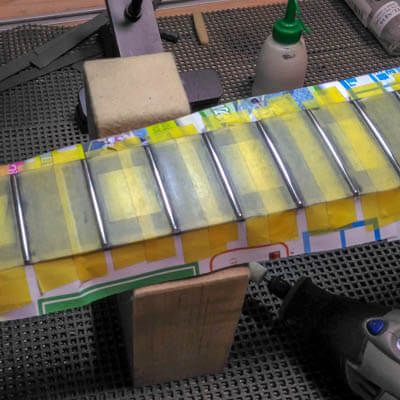

Fitting frets

Wiring electric